Now that you understand the importance of having injection molding companies near me and the factors to consider, let’s discuss how to start your search:

- Online Directories

- Industry Associations

- Local Networking

- Request Quotes

- On-Site Visits

- Contact Previous Clients

The Intricacies of Injection Molding

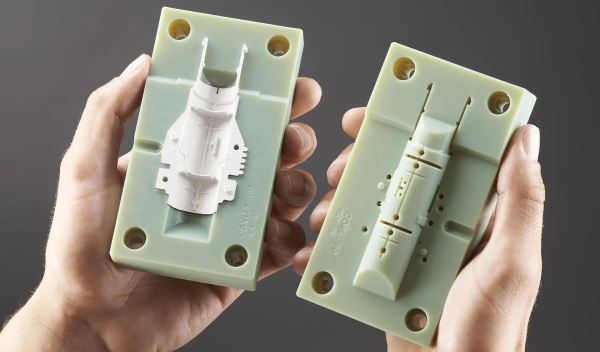

Injection molding is a well-established manufacturing process where molten material, primarily plastic, is injected into a mold to create an array of components and products. This universally recognized technique is pivotal in crafting a diverse range of items – from everyday consumer goods to intricate automotive components, medical devices, and beyond. Opting for an injection molding provides several tangible benefits:

- Swift Execution

- Cost-Effective Solutions

- Transparent Communication

- Uncompromised Quality

Key Steps to Find Plastic Injection Molds for Sale

If you’re in the market for plastic injection molds, here are some practical steps to help you find the right molds for your project:

- Online Marketplace

Explore online marketplaces, such as Alibaba, eBay, and Thomasnet, which often list a variety of plastic injection molds for sale.

- Industry Forums

Participate in industry-specific forums and communities where professionals share information about mold suppliers and sales.

- Trade Shows

Attend trade shows and exhibitions related to manufacturing, where you can connect with mold manufacturers and sellers.

- Direct Inquiries

Reach out to plastic mold manufacturers and suppliers directly to inquire about available molds and request quotes.

- Prototyping Services

Many prototyping services offer plastic injection mold production. Consider utilizing their services to create custom molds for your project.

- Evaluate Options

Compare different mold options, considering factors like mold quality, lead time, and cost. Request samples or prototypes if necessary.

Conclusion

In the world of manufacturing, finding the right injection molding company is imperative. The process, while intricate, plays a pivotal role in producing a multitude of items that fuel various industries. By harnessing online resources, leveraging industry associations, and prioritizing local networking, businesses can secure a reliable partnership. Plastic Injection Molding stands as a testament to the quality and efficiency that’s expected in this domain. In essence, ensuring a meticulous approach in your selection can lead to unparalleled success and innovation in your projects.

FAQs About Plastic Moulding Companies Near Me

Q: What is plastic molding?

A: Plastic molding is a manufacturing process that involves shaping molten plastic material into a desired form using a mold.

Q: Why is it important to choose a local plastic molding company?

A: Local companies offer advantages such as rapid project turnaround, cost efficiency, effective communication, and quality control, all of which are crucial for project success.

Q: How can I determine if a plastic molding company is reliable?

A: Assess their expertise, experience, technology, quality assurance measures, and feedback from past clients.

Q: What types of products can be produced through plastic molding?

A: Plastic molding is used to create a wide range of products, from consumer goods to automotive components and medical devices.

Q: How can I request a quote from a plastic molding company near me?

A: Contact the company directly and provide project details to receive a customized quote.

Q: Are there industry associations that can help me find plastic molding companies in my area

A: Yes, there are industry associations that can provide lists of reputable plastic moulding companies near me.